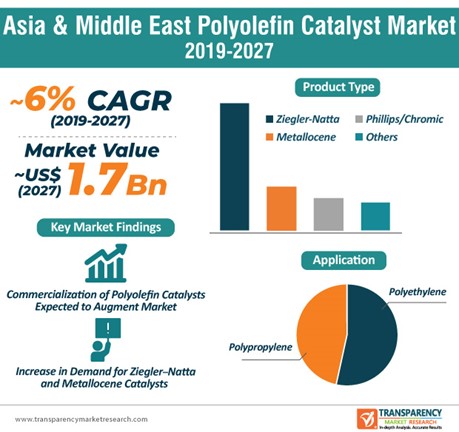

The Asia & Middle East polyolefin catalyst market was valued at US$ 1 Bn in 2018 and is anticipated to expand at a CAGR of ~6% during the forecast period. Among product types, the Ziegler–Natta segment dominated the Asia & Middle East polyolefin catalyst market in 2018. This can be primarily ascribed to high usage of catalysts in the production of both polyethylene and polypropylene, significant yield of polymers, and low cost of the Ziegler–Natta polyolefin catalyst.

Among applications, the polyethylene segment dominated the polyolefin catalyst market in Asia & Middle East in 2018. The high-density polyethylene (HDPE) sub-segment constituted a major share of the polyethylene segment in 2018. This is primarily attributable to the rise in investments in water and wastewater treatment infrastructure and ongoing development of infrastructure in Asia & Middle East, which is boosting the demand for HDPE-based products such as pipes and cables. Asia is estimated to offer immense growth potential to the polyolefin catalyst market in the next few years

Key Drivers and Restraints of Asia & Middle East Polyolefin Catalyst Market

Increasing use of polyolefin in several industries is a major factor driving the Asia & Middle East polyolefin catalyst market. End users of polyolefin include building & construction, consumer goods, electronics, electrical, and automotive industries. Polyolefin comprises commodity thermoplastics such as polyethylene and polypropylene. Easy process-ability, low price, and good chemical and physical properties make polyolefin a preferred choice for use in multiple applications. PE is widely used in the manufacture of various consumer goods, including containers, buckets, pipes, toys, covers, lids, plastic bags, stretch wraps, plastic wraps, sheets, films, bottles, and extrusion-coated paper cartons. Thus, increasing usage of polyolefin is likely to boost the polyolefin catalyst market in Asia & Middle East during the forecast period.

Growing production of polypropylene is another major factor driving the Asia & Middle East polyolefin catalyst market. Polypropylene is a thermoplastic. It is used to produce films, fibers, and tubes, which are employed in a wide range of end-use industries such as packaging, plastics, automotive, and textile. Demand for polypropylene is increasing, owing to the rising demand for lightweight PP-based materials in industries such as automotive and packaging. Demand for polypropylene is increasing, due to its adjustable semi-crystalline morphology, which can be controlled by the polymerization conditions and methodology. These factors are likely to drive the polyolefin catalyst market in Asia & Middle East during the forecast period.

High costs of polyolefin catalysts is a major factor hampering the Asia & Middle East polyolefin catalyst market. Costs of polyolefin catalysts have not been consistent in the last few years, due to new developments taking place in the marketplace. Metallocene and non-phthalate polyolefin catalysts are costly. Average prices of Metallocene and non-phthalate polyolefin catalysts are two times higher than those of the Ziegler–Natta catalyst.

Asia a Highly Lucrative Market for Polyolefin Catalyst in Asia & Middle East

Asia dominates the Asia & Middle East polyolefin catalyst market. Demand for polyolefin catalysts is high in the sub-region, as Asia is a major manufacturer of polypropylene across the globe. Key manufacturers of polyolefin catalysts, such as LyondellBasell Industries Holdings B.V. and Mitsui Chemicals, Inc., own and run facilities in Asia. China dominated the polyolefin catalyst market in Asia in 2018. This can be primarily ascribed to China being a major producer and consumer of polyolefin catalysts in the sub-region and rise in the number of end-use industries in the country. South Korea held a considerable share of the polyolefin catalyst market in Asia in 2018. Manufacturers of polyolefin catalysts in Asia are expanding their manufacturing facilities, owing to increased demand for polypropylene and polyethylene from automobile and home appliances industries in the sub-region.

Asia & Middle East Polyolefin Catalyst Market: Key Developments

On April 11, 2019, Clariant AG announced successful opening of its new high-yield facility for OxyMax PA 690 catalyst at the Petrowidada’s world-scale phthalic anhydride plant in Gresik, East Java, Indonesia. OxyMax PA 690 is a shell-type catalyst, which is produced by using the company’s proprietary fluid-bed coating technology.

On March 26, 2019, BASF opened an innovative research center for catalysts and processes in Ludwigshafen, Germany. The research center has optimized pilot plant facility infrastructure. It has a highly automated testing facility for continuous data supply and professional data management, which would simplify the planning and analysis of experiments. This new pilot plant facility for catalysts and process development would be operated by the company’s global research unit.